Tin Coat Finish . Use it on cutting tools, punches, dies and injection mold components to. tin thin films can be deposited through a process called physical vapor deposition (pvd) to coat substrates. titanium nitride (tin) coating is wear resistant, inert and reduces friction. titanium nitride is an extremely hard, inert, thin film coating that is applied primarily to precision metal parts. Tin coatings effectively reduce abrasive and adhesive. This process involves the deposition of titanium nitride (a compound of titanium and nitrogen) onto the substrate, which could be metal, plastic, or ceramic. titanium carbonitride, blue grey in color, has a hard, smooth finish which offers improved wear and built up edge resistance.

from www.mdpi.com

titanium nitride is an extremely hard, inert, thin film coating that is applied primarily to precision metal parts. titanium nitride (tin) coating is wear resistant, inert and reduces friction. titanium carbonitride, blue grey in color, has a hard, smooth finish which offers improved wear and built up edge resistance. Use it on cutting tools, punches, dies and injection mold components to. Tin coatings effectively reduce abrasive and adhesive. This process involves the deposition of titanium nitride (a compound of titanium and nitrogen) onto the substrate, which could be metal, plastic, or ceramic. tin thin films can be deposited through a process called physical vapor deposition (pvd) to coat substrates.

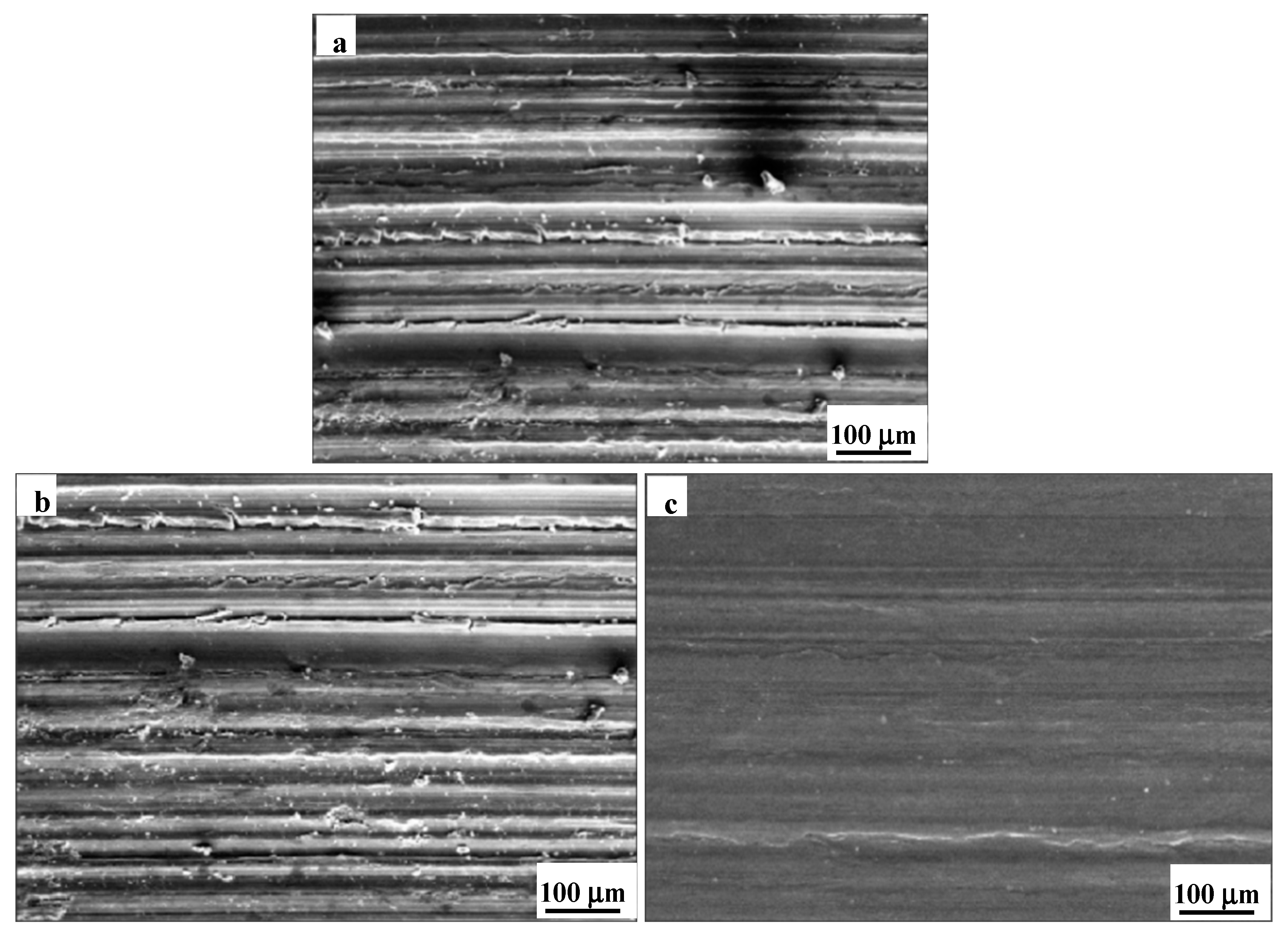

Materials Free FullText Surface Performance of NanoCrN/TiN Multi

Tin Coat Finish This process involves the deposition of titanium nitride (a compound of titanium and nitrogen) onto the substrate, which could be metal, plastic, or ceramic. titanium nitride is an extremely hard, inert, thin film coating that is applied primarily to precision metal parts. titanium nitride (tin) coating is wear resistant, inert and reduces friction. Tin coatings effectively reduce abrasive and adhesive. This process involves the deposition of titanium nitride (a compound of titanium and nitrogen) onto the substrate, which could be metal, plastic, or ceramic. Use it on cutting tools, punches, dies and injection mold components to. tin thin films can be deposited through a process called physical vapor deposition (pvd) to coat substrates. titanium carbonitride, blue grey in color, has a hard, smooth finish which offers improved wear and built up edge resistance.

From www.riversidesheetmetal.net

Uginox patina k44 Tin Terne Coated Stainless Steel sheet metal Tin Coat Finish Tin coatings effectively reduce abrasive and adhesive. titanium carbonitride, blue grey in color, has a hard, smooth finish which offers improved wear and built up edge resistance. tin thin films can be deposited through a process called physical vapor deposition (pvd) to coat substrates. Use it on cutting tools, punches, dies and injection mold components to. titanium. Tin Coat Finish.

From classic-kontor.com

Filson Tin Cloth Field Jacket Tan Classic Kontor Tin Coat Finish Tin coatings effectively reduce abrasive and adhesive. titanium nitride is an extremely hard, inert, thin film coating that is applied primarily to precision metal parts. This process involves the deposition of titanium nitride (a compound of titanium and nitrogen) onto the substrate, which could be metal, plastic, or ceramic. titanium carbonitride, blue grey in color, has a hard,. Tin Coat Finish.

From www.metalsteelsheet.com

Prime Electrolytic Tinplate Sheet with Temper15 Tin Coating 2.8g/M2 Tin Coat Finish titanium nitride (tin) coating is wear resistant, inert and reduces friction. Use it on cutting tools, punches, dies and injection mold components to. titanium nitride is an extremely hard, inert, thin film coating that is applied primarily to precision metal parts. This process involves the deposition of titanium nitride (a compound of titanium and nitrogen) onto the substrate,. Tin Coat Finish.

From dxoxhjjtq.blob.core.windows.net

Metal Paint Finishes at Ellen McDonald blog Tin Coat Finish Use it on cutting tools, punches, dies and injection mold components to. Tin coatings effectively reduce abrasive and adhesive. titanium carbonitride, blue grey in color, has a hard, smooth finish which offers improved wear and built up edge resistance. This process involves the deposition of titanium nitride (a compound of titanium and nitrogen) onto the substrate, which could be. Tin Coat Finish.

From www.basketwholesalers.com

6.5" Tin Pot Brown Powder Coat Finish Tin Coat Finish Use it on cutting tools, punches, dies and injection mold components to. tin thin films can be deposited through a process called physical vapor deposition (pvd) to coat substrates. titanium nitride (tin) coating is wear resistant, inert and reduces friction. Tin coatings effectively reduce abrasive and adhesive. This process involves the deposition of titanium nitride (a compound of. Tin Coat Finish.

From www.dovey.us

Tungsten / Carbide Blades Dovey Corporation Tin Coat Finish This process involves the deposition of titanium nitride (a compound of titanium and nitrogen) onto the substrate, which could be metal, plastic, or ceramic. titanium carbonitride, blue grey in color, has a hard, smooth finish which offers improved wear and built up edge resistance. tin thin films can be deposited through a process called physical vapor deposition (pvd). Tin Coat Finish.

From advancedplatingtech.com

Tin Plating Services MILT10727, ASTM B545 and AMS 2408 Tin Coat Finish titanium nitride (tin) coating is wear resistant, inert and reduces friction. titanium nitride is an extremely hard, inert, thin film coating that is applied primarily to precision metal parts. tin thin films can be deposited through a process called physical vapor deposition (pvd) to coat substrates. This process involves the deposition of titanium nitride (a compound of. Tin Coat Finish.

From www.basketwholesalers.com

6.5" Tin Pot Brown Powder Coat Finish Tin Coat Finish Tin coatings effectively reduce abrasive and adhesive. tin thin films can be deposited through a process called physical vapor deposition (pvd) to coat substrates. This process involves the deposition of titanium nitride (a compound of titanium and nitrogen) onto the substrate, which could be metal, plastic, or ceramic. Use it on cutting tools, punches, dies and injection mold components. Tin Coat Finish.

From www.globalpiyasa.com

Tin Coating Buy Tin Coating product on Tin Coat Finish tin thin films can be deposited through a process called physical vapor deposition (pvd) to coat substrates. Tin coatings effectively reduce abrasive and adhesive. titanium nitride is an extremely hard, inert, thin film coating that is applied primarily to precision metal parts. This process involves the deposition of titanium nitride (a compound of titanium and nitrogen) onto the. Tin Coat Finish.

From carltoncooke.com

Metal Finishes Metal Finishing, Plating, Polishing, Restoration NJ Tin Coat Finish This process involves the deposition of titanium nitride (a compound of titanium and nitrogen) onto the substrate, which could be metal, plastic, or ceramic. titanium nitride (tin) coating is wear resistant, inert and reduces friction. titanium carbonitride, blue grey in color, has a hard, smooth finish which offers improved wear and built up edge resistance. tin thin. Tin Coat Finish.

From www.eifeler-austria.com

AllRound Refinement Coating TiN Eifeler HighTech Coatings Tin Coat Finish This process involves the deposition of titanium nitride (a compound of titanium and nitrogen) onto the substrate, which could be metal, plastic, or ceramic. titanium nitride (tin) coating is wear resistant, inert and reduces friction. Tin coatings effectively reduce abrasive and adhesive. titanium nitride is an extremely hard, inert, thin film coating that is applied primarily to precision. Tin Coat Finish.

From www.youtube.com

TiN Barrel Coating YouTube Tin Coat Finish Use it on cutting tools, punches, dies and injection mold components to. titanium carbonitride, blue grey in color, has a hard, smooth finish which offers improved wear and built up edge resistance. Tin coatings effectively reduce abrasive and adhesive. titanium nitride (tin) coating is wear resistant, inert and reduces friction. This process involves the deposition of titanium nitride. Tin Coat Finish.

From www.pioneermetal.com

Zinc Plating vs. Zinc Flake Coating Pioneer Metal Finishing Tin Coat Finish tin thin films can be deposited through a process called physical vapor deposition (pvd) to coat substrates. titanium nitride is an extremely hard, inert, thin film coating that is applied primarily to precision metal parts. This process involves the deposition of titanium nitride (a compound of titanium and nitrogen) onto the substrate, which could be metal, plastic, or. Tin Coat Finish.

From www.dti.dk

New TiN coating for temperaturesensitive base materials Danish Tin Coat Finish titanium nitride (tin) coating is wear resistant, inert and reduces friction. This process involves the deposition of titanium nitride (a compound of titanium and nitrogen) onto the substrate, which could be metal, plastic, or ceramic. tin thin films can be deposited through a process called physical vapor deposition (pvd) to coat substrates. titanium nitride is an extremely. Tin Coat Finish.

From aerospacemetalsllc.com

What is Tin Plating? Aerospace Metals Tin Coat Finish This process involves the deposition of titanium nitride (a compound of titanium and nitrogen) onto the substrate, which could be metal, plastic, or ceramic. Tin coatings effectively reduce abrasive and adhesive. Use it on cutting tools, punches, dies and injection mold components to. titanium carbonitride, blue grey in color, has a hard, smooth finish which offers improved wear and. Tin Coat Finish.

From www.tinindianperformance.com

Black Satin Powder Coating Tin Indian Performance Tin Coat Finish titanium nitride is an extremely hard, inert, thin film coating that is applied primarily to precision metal parts. Use it on cutting tools, punches, dies and injection mold components to. This process involves the deposition of titanium nitride (a compound of titanium and nitrogen) onto the substrate, which could be metal, plastic, or ceramic. titanium nitride (tin) coating. Tin Coat Finish.

From texasgoldroofing.com

What Is The Best Coating For Metal Roof? Roofing Contractors Houston Tin Coat Finish This process involves the deposition of titanium nitride (a compound of titanium and nitrogen) onto the substrate, which could be metal, plastic, or ceramic. tin thin films can be deposited through a process called physical vapor deposition (pvd) to coat substrates. Tin coatings effectively reduce abrasive and adhesive. Use it on cutting tools, punches, dies and injection mold components. Tin Coat Finish.

From jnltech.co.kr

METALLIONCoating 제이앤엘테크 J&L TECH Tin Coat Finish tin thin films can be deposited through a process called physical vapor deposition (pvd) to coat substrates. titanium carbonitride, blue grey in color, has a hard, smooth finish which offers improved wear and built up edge resistance. This process involves the deposition of titanium nitride (a compound of titanium and nitrogen) onto the substrate, which could be metal,. Tin Coat Finish.